The legendary model 100 series winders have been manufactured for nearly 30 years. Itasca Automation Systems Model 100 Programmable Coil Winder is perfect for companies requiring quick change over, program storage for multiple programs, job shops running multiple varieties of coils, or labs developing new coil proto-types. The Model 100 is a fully programmable embedded PC, capable of performing the most complex programming requirements.

The control allows you to change the pitch, traverse length, Tension and rpm at any turn count within the wind command.

Below are some of the options we offer on the model 100 winders: Foot Pedal, Hot Air Gun, Skeiner, Programmable Electronic Tension, Eyelet Nozzle and V roller wire guide, Liquid Bond Attachment as well as extended I/O.

More Product Information

| Model | 100-3 | 100-6 |

|---|---|---|

| Spindle Speed | 12,000 Max | 12,000 Max |

| Wire Size | 46-14 AWG | 46-14 AWG |

| Pitch Resolution | .00001" | .00001" |

| Traverse Length | 3" | 6" |

| Max Coil Diameter | 4.5" | 4.5" |

| Program Storage | 7,000 Lines of Code | 7,000 Lines of Code |

| Power Supply | 120 or 230 Volts | 120 or 230 Volts |

| Dimensions | 19"W x 20"H x 20"D | 25"W x 20"H x 20"D |

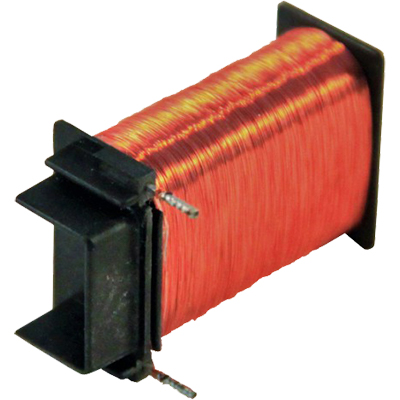

The Model 100 Series coil winders are precision machines designed for winding coils of wire or other materials. They are commonly used in electronics, electrical engineering, automotive, and telecommunications industries. These coil winders offer high accuracy, control, and efficiency, making them an essential tool for manufacturing processes that require consistent and reliable coil winding.

Let’s review the key features and benefits of our Model 100 Series coil winders. We will discuss their performance, ease of use, build quality, and the overall value they provide to users. Whether you’re a professional in the industry or an enthusiast looking for a reliable coil winding solution, look no further than Itasca Automation Systems.

Design and Construction

Our Model 100 Series coil winders are designed for industrial applications and are known for their accuracy, efficiency, and reliability. Here’s a general overview of the design and construction of this product:

Base: The coil winder is built utilizing sturdy machined castings. The high-quality base has two holes in it to allow it to be bench mounted in any given configuration. The small size allows for the small floor space required and can also be set up to have two machines side by side with one operator running both machines.

Spindle System: The coil-winding spindle holds the core or bobbin on which the wire is wound. It rotates smoothly and consistently during the winding process. A Brushless Servo motor drives the spindle that controls the rotational speed and direction.

Wire Feeding Mechanism: The Model 100 Series coil winders feature a wire-feeding mechanism that guides the wire from the supply spool to the winding spindle. This mechanism ensures proper tension and alignment of the wire during winding. It may include wire guides, programmable electronic tensioning devices, and wire clamps to secure the wire in place.

Control System: The coil winder is equipped with a control system that allows the operator to set various parameters such as winding speed, number of turns, direction, pitch, and tension. The control system may include a user-friendly interface, such as a touch screen or control panel, for easy operation and programming.

Winding Head: The winding head holds the winding tool or mandrel that determines the shape and size of the coil. It accommodates different winding tools based on the application’s specific requirements. The winding head may be adjustable for various coil sizes and configurations.

Motor Drive System: The Model 100 Series coil winders are driven by high-precision motors that precisely control the winding process. These are typically servo or stepper motors, known for their accuracy and repeatability. The motor drive system is connected to the control system and responds to the commands given by the operator.

Safety Features: Coil winders often incorporate safety features to protect the operator and the machine. These features may include emergency stop buttons, protective covers, sensors to detect wire breakage or tangles, and overload protection mechanisms.

Key Features and Functions

The Model 100 Series electrical core winder offers several key features and functions that enhance productivity and precision in the winding process. While specific features may vary among different manufacturers, here are some standard features and functions associated with the Model 100 Series coil winders:

Programmability: The Model 100 Series coil winders are typically programmable machines that allow users to define the desired winding parameters and patterns. This includes setting the number of turns, wire tension, winding speed, direction, and other variables to achieve precise and consistent winding results. The control allows you to vary the speed, pitch, length of traverse, and tension within a coil.

Multiple winding modes: These coil winders often support various winding modes to accommodate different coil types and configurations. Standard modes include single-layer winding, multi-layer winding, interleave winding, and random winding, among others. This versatility enables the winding of coils for a wide range of applications.

User-friendly interface: The coil winders have user-friendly interfaces, typically featuring a control panel or a touchscreen display. These interfaces allow operators to quickly input and modify winding parameters, select winding modes, and monitor the winding process in real-time.

Automatic wire guidance: Model 100 Series coil winders often include automatic wire guidance systems for proper winding. These systems guide the wire from the supply spool to the wound component, maintaining proper tension and preventing wire tangling or misalignment during the winding process. An Eyelet Nozzle or V groove pulley are normal options with customized options available.

Wire tension control: Maintaining consistent wire tension is crucial for achieving high-quality coils. Coil winders in the Model 100 Series are designed with wire tension control mechanisms that adjust the tension throughout the winding process, compensating for wire length and diameter changes.

Program Storage: All Model 100 Series coil winders are capable of holding several hundred programs that can be selected from the user interface. Operators can save and recall winding programs, which will assure the programmed tension will be the same every time the program is selected.

Comparison to Other Winders in the Market

The Model 100 Series coil winders stand out in the market due to their phenomenal features and superior performance. Compared to other winders, the Model 100 Series offers unparalleled precision in winding coils, ensuring optimal electrical performance.

These winders have advanced automation capabilities, allowing for efficient and consistent production, reducing labor costs, and increasing overall productivity.

With their unmatched quality, efficiency, and reliability, the Model 100 Series coil winders are the top choice for manufacturers needing high-performance winding solutions.

Verdict

Model 100 Series Winders are the best on the market. If you’re ready to revolutionize your winding operations and maximize efficiency, look no further than the Model 100 Series Winders from Itasca Automation Systems! Whether in the manufacturing, packaging, or textile industry, our cutting-edge winders will streamline your processes and boost productivity like never before.

Take advantage of this incredible opportunity to revolutionize your winding operations! Order now by contacting us at +1 (920) 868-3266. You can also email us at sales@itascaautosys.com or message us online for more information on coil winders.