In today’s fast-paced manufacturing landscape, minimizing downtime is a top priority for businesses across industries. For manufacturers in the coil winding sector, efficient and reliable processes are essential to meet tight deadlines and high-quality standards.

At Itasca Automation Systems, we understand the critical role precision-engineered solutions play in reducing downtime. With our expertise in designing and manufacturing innovative winder machines and automated systems, we help clients maintain operational efficiency and stay ahead of the competition.

Understanding Downtime in Coil Winding Operations

Downtime in coil winding operations can result from:

- Equipment failure

- Inefficiencies in the production process

- Operator error

The impact of downtime includes:

- Increased costs

- Disrupted supply chains

- Delayed product delivery

Addressing these challenges requires:

- Equipment reliability

- Process optimization

- Advanced technology

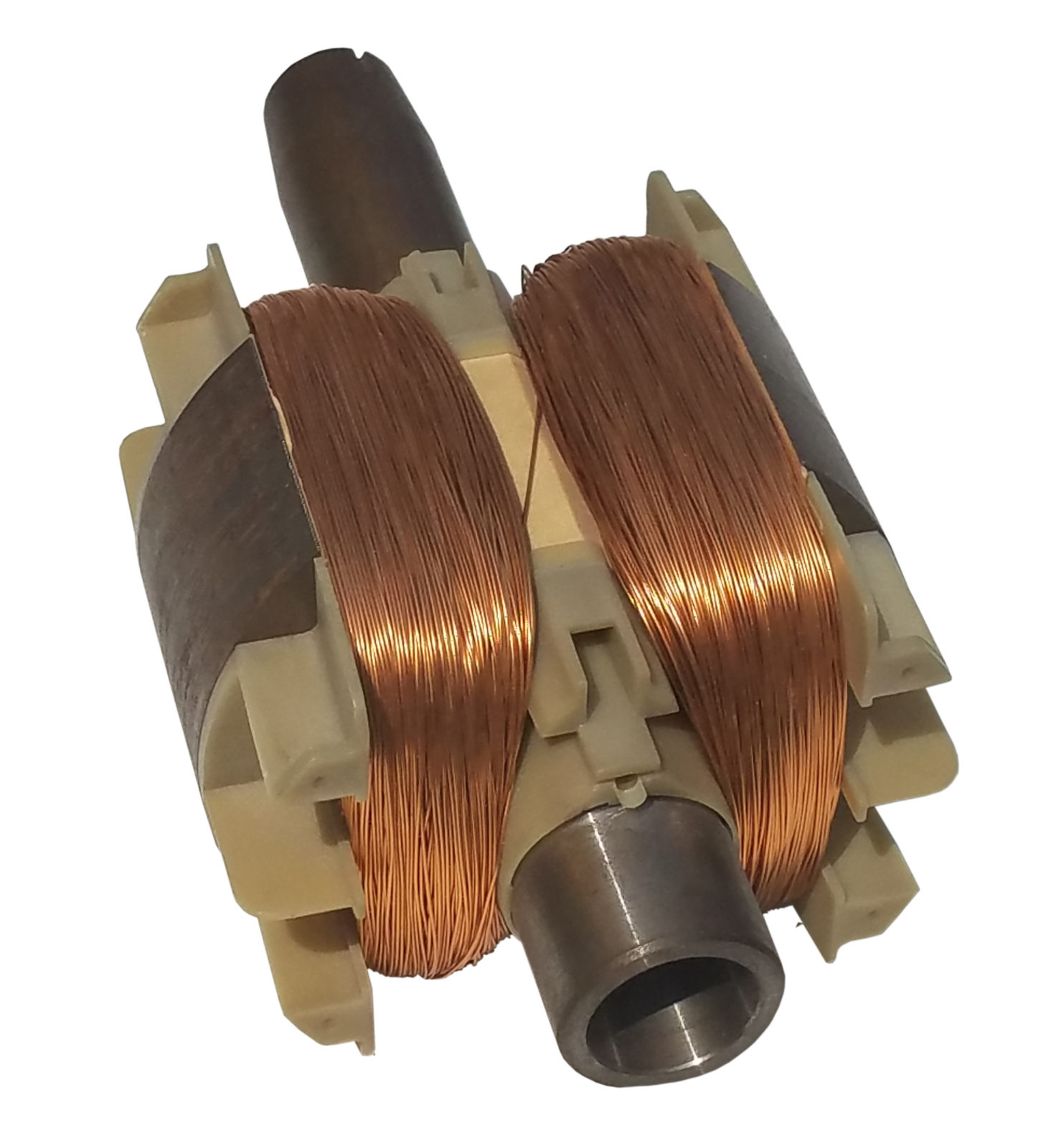

The Role of Precision Automated Winder Machines

A well-designed winder machine is the cornerstone of any efficient coil winding process. These machines ensure:

- Precise dimensions

- Consistent quality across production runs

At Itasca Automation Systems, our automated multi-spindle winders combine:

- Precision

- Speed

- Adaptability

Key Advantages:

- Reduced manual intervention minimizes errors and faulty coils.

- Modular design ensures easy maintenance and upgrades, enhancing reliability.

Key Features of Efficient Coil Winding Solutions

To effectively reduce downtime, coil winding machines should include:

1. Advanced Automation

- Programmable controls and real-time monitoring

- Seamless, uninterrupted production with minimal manual adjustments

2. Modular Machine Design

- Simplified maintenance and quick part replacements

- Lean, modular design for minimal repair time

3. Multi-Function Capabilities

- Integration of winding, terminal insertion, soldering, and testing

- Streamlined production process to reduce delays

4. Robust Testing and Quality Assurance

- Real-time defect identification and correction

- Prevention of costly rework and production delays

5. Scalability and Customization

- Tailored solutions to meet unique manufacturing requirements

- Optimal performance for specific production goals

Benefits of Reducing Downtime with Efficient Solutions

Investing in high-quality coil winding machinery delivers significant benefits:

- Increased Productivity

High-speed, efficient machines boost overall output to meet market demands. - Cost Savings

Minimized downtime reduces emergency repairs and energy consumption. - Improved Product Quality

Precision engineering ensures defect-free production, enhancing customer satisfaction. - Enhanced Flexibility

Machines adapt to varying coil specifications, enabling quick responses to market trends.

The Itasca Automation Systems Advantage

At Itasca Automation Systems, we deliver cutting-edge solutions tailored to client needs. Our advantages include:

- Advanced 3D CAD tools for superior engineering

- Precision craftsmanship inspired by Door County’s shipbuilding tradition

- Sustainable operations aligned with our values of quality and growth

Real-World Applications of Our Solutions

Our coil winding solutions support industries such as:

- Automotive: High-precision coils for electric motors.

- Aerospace: Automated systems for critical components meeting stringent standards.

- Medical Devices: Compact coils for hearing aids and MRI machines.

Continuous Innovation in Coil Winding

We stay ahead of industry demands through continuous innovation:

- Integration of IoT for real-time monitoring

- Development of modular components for versatility

Collaborating for Success

Our partnership-driven approach ensures:

- Solutions aligned with client-specific challenges

- Long-term relationships built on trust and mutual success

Contact Us Today

Don’t let downtime hinder your operations. Partner with Itasca Automation Systems for innovative, reliable, and cost-effective coil winding solutions crafted with precision in Wisconsin.

Contact us today to optimize your processes and drive success forward!

Comments are closed