Coil winding machines play a crucial role in manufacturing various electrical components, such as transformers, inductors, and motors. These machines are designed to automate the process of winding wire around a core to create a coil with a specific number of turns and configurations.

A coil winding machine has several components, each critical to ensuring the efficiency, accuracy, and reliability of the winding process.

Wire Tensioning Device

One key component of a coil winding machine is the wire tensioning device. This device maintains the proper tension on the wire as it is wound around the core. Proper tension is essential to ensure consistent winding quality and prevent wire breakage or slippage during the winding process.

Wire tensioning devices come in various forms, such as mechanical, pneumatic, and electronic tensioners. The type of tensioning device used will depend on the specific requirements of the winding process, such as the wire gauge, material, and winding speed.

Wire Guide

Another important component of a coil winding machine is the wire guide. The wire guide accurately guides the wire onto the core during the winding process. It ensures the wire is evenly distributed around the core and maintains the desired winding pattern.

Wire guides can be manual or automatic, depending on the level of precision required for the winding process. Automatic wire guides are equipped with sensors and actuators to adjust the position of the wire in real time, ensuring precise wire placement and consistent winding quality.

Core Holding Mechanism

The core holding mechanism is responsible for securely holding the core in place during the winding process. It prevents the core from moving or shifting as the wire is being wound around it, ensuring accurate coil geometry and winding pattern.

Core holding mechanisms can be designed as manual clamps or automatic chucks, depending on the type and size of the core being wound. Automatic core holding mechanisms are equipped with sensors and actuators to adjust the clamping force and position of the core, ensuring optimal winding performance.

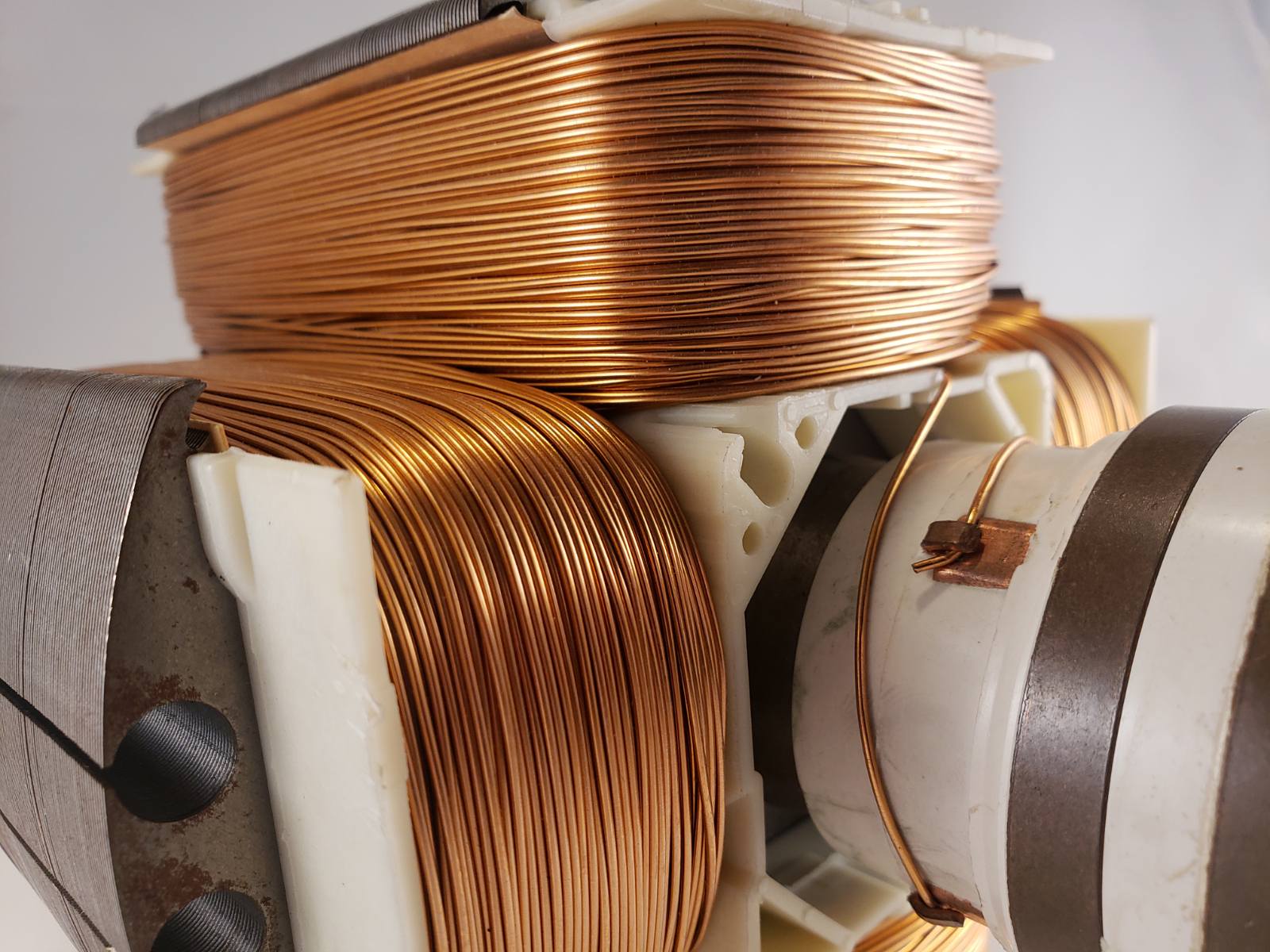

Winding Head

The winding head is the component of the coil winding machine that houses the wire spool and guides the wire onto the core. It is responsible for controlling the speed and direction of the wire as it is being wound around the core, ensuring precise winding patterns and turns count.

Winding heads can be designed as single or multiple spindle configurations, depending on the requirements of the winding process. Multiple spindle winding heads allow for simultaneous winding of multiple coils, increasing production efficiency and throughput.

Programmable Controller

The programmable controller is the brain of the coil winding machine and is responsible for controlling and coordinating the operation of all components. It stores and executes winding programs, monitors process parameters, and ensures accurate and repeatable winding results.

Modern coil winding machines have advanced programmable controllers that offer touchscreen interfaces, networking capabilities, and recipe management. These controllers allow operators to easily set up and customize winding parameters, monitor process performance, and troubleshoot any issues that may arise during operation.

Safety Features

Safety features are essential components of a coil winding machine to ensure the safety of operators and prevent accidents or injuries. These features may include emergency stop buttons, safety interlocks, guards, and sensors to detect and respond to potential hazards.

Coil winding machine manufacturers must design their machines in compliance with industry safety standards and regulations. This includes conducting risk assessments, implementing safety protocols, and providing proper training to operators on safe machine operation.

Contact Us Today

The different components of a coil winding machine work together to automate the winding process, ensuring the efficient production of high-quality coils. Itasca Automation Systems specializes in designing and manufacturing precision automated machines for the coil winding industry, including wire winding machines. Our expertise and commitment to customer satisfaction make us a reliable partner for companies looking to enhance their coil winding operations.

Contact us today to learn how our innovative solutions can help optimize your coil winding processes and improve your production efficiency.

Remember, Itasca Automation Systems is the partner you can trust for dependable, high-quality automated solutions for coil winding machines.

Comments are closed