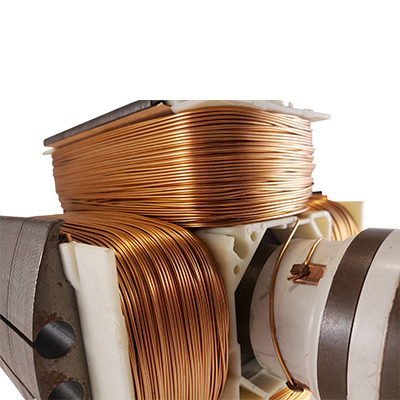

Precision is paramount in manufacturing and electrical engineering. One such example where precision takes center stage is the winding of coils. Whether in transformers, motors, inductors, or other electromagnetic devices, coils are fundamental components that demand meticulous attention to detail during manufacturing. Heavy duty single spindle coil winders play a critical role in the equipment used for this purpose. These machines can wind various wire sizes and materials onto various core shapes and sizes, ensuring that the final product performs efficiently and reliably.

Understanding Single Spindle Coil Winders

Before diving into specific applications, it’s crucial to understand what heavy duty single spindle coil winders are and how they function. These machines are designed to wind wire onto a single bobbin, core, or spool at a time. They are equipped with one spindle that rotates the workpiece, while a guide moves the wire in a specific pattern to ensure even distribution and optimal coil formation.

The heavy duty aspect refers to the machine’s ability to handle larger, more complex tasks, such as winding thicker wire, managing high-tension winding, or producing coils with large diameters and high winding counts. These winders are often automated and capable of performing complex winding patterns and controlling variables like wire tension, speed, and layer precision.

They are designed for reliability, accuracy, and endurance—traits vital in industries that rely on highly sensitive electromagnetic components.

Key Features of Heavy Duty Single Spindle Coil Winders

Heavy duty single spindle coil winders, like those developed by Itasca Automation Systems, incorporate several advanced features that allow them to meet the demanding needs of modern industrial applications. These features include:

- Precision Control: Advanced winding machines offer programmable controls for precise wire tension, feed rate, and winding pattern.

- High Durability: Built to withstand the rigors of industrial environments, these machines are made from high-quality materials that offer longevity and stability.

- Flexibility: Single spindle winders can be adapted for different winding tasks, from small and intricate coils to larger, heavy duty coils.

- Automated Capabilities: Many single spindle winders come equipped with automation features, such as touch-screen interfaces, data logging, and programmable winding sequences.

- Safety Mechanisms: These machines are equipped with features to prevent wire breakage and overheating, ensuring operator safety and product quality.

These characteristics make heavy duty single spindle coil winders ideal for a wide range of industries and applications.

Applications of Heavy Duty Single Spindle Coil Winders

Transformers

Transformers are a staple in the power transmission and distribution industry, serving to step up or down the voltage in power lines. The winding of transformer coils is a critical process that demands a high degree of precision to ensure efficiency and minimize energy losses.

Heavy duty single spindle coil winders are commonly used to produce transformer coils. Their ability to handle larger wires, manage precise tension, and execute complex winding patterns makes these machines invaluable in the creation of both small and large transformer coils. The quality of the winding process directly influences the performance and longevity of the transformer, making the precision of a wire coiler essential to the success of the final product.

Electric Motors

Electric motors are everywhere, from household appliances to industrial machinery. Each motor relies on carefully wound coils to create the electromagnetic fields necessary for operation. Different types of motors, such as induction motors, synchronous motors, and stepper motors, require specific winding techniques that can be achieved using a heavy duty single spindle coil winder.

The precision and durability of these winders ensure that the wire is wound uniformly, which is critical for the motor’s performance and efficiency. Whether winding the stator or rotor coils, a wire coiler ensures the motor operates reliably and with optimal energy efficiency.

Inductors

Inductors are used in a variety of applications, from energy storage in power supplies to filtering in electrical circuits. Like transformers, the performance of inductors is heavily dependent on the quality of the coils wound inside them. Variations in wire tension or misalignments during the winding process can result in inefficiencies or complete malfunction of the inductor.

Heavy duty single spindle coil winders play a pivotal role in winding high-performance inductors. These machines offer the precision necessary to create uniform coils that maximize inductance while minimizing losses. Whether producing small inductors for electronics or large inductors for industrial power systems, single spindle coil winders ensure that the final product meets stringent quality standards.

Solenoids

Solenoids, essentially electromagnetic coils, are used in various applications, including actuators, valves, and sensors. A solenoid’s performance is directly related to the precision of the coil winding process. Heavy duty single spindle coil winders are commonly used to produce the tight, even windings required for efficient solenoid operation.

These machines can wind fine wire at precise tension, ensuring that the solenoid generates the correct magnetic field strength and operates reliably over its service life. In applications where solenoids are used for critical functions, such as medical devices or industrial automation, the reliability of the winding process is non-negotiable.

Generators

Generators, both small and large, rely on coils to convert mechanical energy into electrical energy. Like transformers and motors, the quality of a generator’s coil windings directly influences its efficiency and reliability. Heavy duty single spindle coil winders are essential in the production of generator coils, ensuring that the wire is wound uniformly and at the correct tension.

For large industrial generators, these machines can handle the high-tension, heavy-gauge wires required to produce high-output coils. The precision these machines offer ensures that the generator operates at peak performance, minimizing losses and maximizing energy output.

High-Frequency RF Coils

Radiofrequency (RF) coils are used in various applications, including telecommunications, medical imaging, and broadcasting. These coils require highly precise winding techniques to ensure they operate at the correct frequency and with minimal signal loss. Heavy duty single spindle coil winders, with their ability to control wire tension and winding speed, are crucial in producing RF coils.

For these applications, the ability to automate the winding process ensures consistency across multiple coils, which is essential for maintaining performance standards in sensitive RF systems. Whether winding coils for medical imaging equipment or radio transmitters, a wire coiler ensures that the final product meets strict quality standards.

Custom Coils for Specialized Applications

Many industries require custom coils for specialized applications. These may include aerospace, automotive, and defense sectors, where electromagnetic components need to meet unique design requirements. Heavy duty single spindle coil winders offer the flexibility needed to create custom coils with specific wire sizes, winding patterns, and insulation materials.

For example, in the aerospace industry, coils used in sensors and actuators must be lightweight yet robust enough to withstand harsh environmental conditions. Precision wire coilers ensure that the coils are manufactured to exact specifications, ensuring both performance and durability.

Why Choose Itasca Automation Systems?

Itasca Automation Systems specializes in designing and manufacturing precision coil winding equipment tailored to the needs of various industries. Our heavy duty single spindle coil winders are built with precision and durability in mind, making them the ideal choice for manufacturers seeking reliable winding solutions. Whether you’re winding coils for transformers, motors, or custom applications, Itasca Automation Systems’ machines provide the performance and flexibility needed to meet your production goals.

By choosing Itasca Automation Systems, you are investing in:

- Made in the USA quality: All of Itasca’s machines are designed and manufactured in the United States, ensuring high-quality craftsmanship and adherence to industry standards.

- Customizable solutions: Itasca works with clients to design coil winding equipment that meets specific requirements, offering tailored solutions for unique production challenges.

- State-of-the-art technology: Our machines feature the latest automation and control technologies, ensuring precision, efficiency, and ease of use.

Contact Us Today

Itasca Automation Systems is here to help if you need precision coil winding solutions. Our expertise in designing heavy duty single spindle coil winders ensures that you’ll receive a machine capable of meeting the demands of your production line. Contact us today to learn more about how our innovative technology can transform your coil winding operations and take your business to the next level.

Comments are closed