The modern industrial landscape has numerous specialized machines designed to streamline various manufacturing processes. Among these, coil winding machines stand out for their essential role in producing components that are fundamental to a wide range of electronic and electrical devices. From transformers and motors to inductors and sensors, coil winding machines are integral to the creation of these components.

Understanding Coil Winding Machines

Purpose and Functionality

A coil winding machine is designed to wrap wire around a core at its most basic. This seemingly simple process is instrumental in creating components that can store electromagnetic energy, transform voltages, or create magnetic fields. The precision and consistency required in this winding process necessitate highly specialized machinery.

A transformer winding machine, for instance, must wind several layers of wire with impeccable accuracy to ensure the proper functioning of the transformer. Similarly, other types of coil winding machines cater to the specific requirements of diverse industries, offering the precision and adaptability needed to meet stringent quality standards.

Types of Coil Winding Machines

A broad spectrum of coil winding machines is tailored to specific applications and requirements. These can be broadly categorized into automated and manual winding machines.

Automated Coil Winding Machines

Automated winding machines are prevalent in high-volume production environments. These machines provide superior consistency and precision, and they are capable of repeated cycles without fatigue. Among the automated machines, multi-spindle winders are especially noteworthy. These machines allow for the simultaneous winding of multiple coils, drastically improving efficiency and throughput. Automated machines often feature advanced controls for wire tension, speed, and layering, integrating additional processes such as soldering, taping, and testing.

Manual Coil Winding Machines

Manual winding machines, on the other hand, are often used for smaller production runs or prototyping. These machines provide flexibility and control, typically being adjustable for various applications. While they may not offer the same level of consistency as automated machines, manual winding machines are invaluable in settings where customization and adaptability are key.

Core Components of Coil Winding Machines

Though there are many types of coil winding machines, certain components are universal across nearly all of them. Understanding these components provides insight into how these machines operate and the level of precision they can achieve.

Spindle

The spindle, or mandrel, is the core component around which the wire is wound. In most machines, the spindle is adjustable to accommodate various sizes and types of cores. As the name suggests, multi-spindle machines feature multiple spindles to allow for the simultaneous winding of several coils.

Wire Guide

The wire guide ensures that the wire is laid evenly across the core during the winding process. This component is critical for maintaining the winding’s uniformity and precision.

Tension Control System

The tension control system regulates the tension of the wire as it is wound onto the core. Proper tension is necessary to prevent slack or breakage, contributing significantly to the overall quality of the wound coil.

Control Unit

Modern coil winding machines often come equipped with an advanced control unit, which allows for the programming and automation of various aspects of the winding process, such as speed, tension, and layering patterns. These control units can vary from simple manual systems to sophisticated computer-controlled interfaces.

Applications of Coil Winding Machines

The applications of coil winding machines are as varied as the types of coils they produce. Key industries that rely on these machines include electronics, automotive, aerospace, and telecommunications.

Transformers

One of the most ubiquitous applications of coil winding machines is in the manufacturing of transformers. Transformer winding machines are specifically designed to handle the precision and complexity involved in winding the multiple layers of wire necessary for these components. Proper winding is crucial for the efficient operation and longevity of transformers and is indispensable in power transmission and distribution systems.

Electric Motors

Electric motors, used in countless applications from household appliances to industrial machinery, also rely on meticulously wound coils. The performance of electric motors is directly linked to the quality of the winding process, underlining the importance of precision coil winding machines in their manufacture.

Inductors and Chokes

Inductors and chokes are essential components in electronic circuits, serving functions such as filtering, signal modulation, and energy storage. The precision winding required for these components necessitates advanced coil winding machines capable of maintaining tight tolerances.

Medical Devices

Precision and reliability are paramount in the medical field. Coils used in medical devices such as MRI machines and various sensors must be manufactured to exacting standards. Coil winding machines provide the consistency and accuracy required to meet these standards, ensuring the safe and effective operation of medical equipment.

Innovations in Coil Winding Technology

The coil winding industry has seen significant technological advancements in recent years. Modern coil winding machines leverage cutting-edge technologies such as 3D CAD design, modular machine design, and automation systems to enhance precision and efficiency.

3D CAD Design

Modern 3D CAD tools allow for the detailed modeling of coil winding machines, enabling engineers to design machines that meet specific customer requirements. This approach facilitates the creation of customized solutions that optimize performance and fit seamlessly within existing production environments.

Modular Machine Design

Lean modular machine design enhances flexibility and adaptability, enabling manufacturers to respond swiftly to changing production demands. This approach simplifies maintenance and upgrades, reduces downtime, and extends the machinery’s lifespan.

Automation and Integration

Automation is perhaps the most significant trend in coil winding technology. Automated machines not only improve consistency and throughput but also reduce the risk of human error. Integration of additional processes such as soldering, taping, and testing within the winding machine further streamlines production, improving efficiency and reducing costs.

Choosing the Right Coil Winding Machine

Selecting the right coil winding machine is critical for achieving optimal performance and efficiency in manufacturing. Factors to consider include the specific application, production volume, and required precision.

Custom Solutions

Given the diversity of applications and requirements, there is no one-size-fits-all solution. Partnering with a manufacturer that offers customized solutions can ensure that the machine is designed to meet specific needs, providing the best possible performance.

Support and Service

In addition to the machine itself, the level of support and service the manufacturer provides is crucial. This includes not only initial setup and training but also ongoing maintenance and troubleshooting to ensure the machine operates at peak efficiency.

Partnering with Itasca Automation Systems

In the world of coil winding, precision, efficiency, and reliability are paramount. At Itasca Automation Systems, we specialize in designing and manufacturing precision automated machines for the coil winding industry. Our dedicated engineers work collaboratively with customers to develop tailored solutions using modern 3D CAD tools and lean modular machine design approaches.

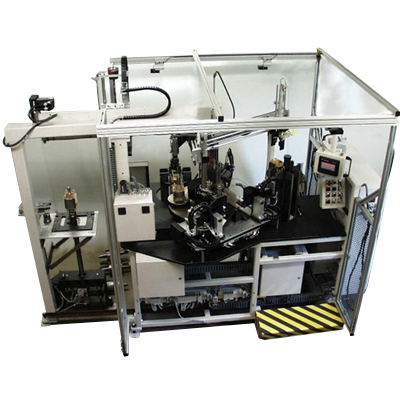

Our products include automated multi-spindle winders, terminal insertion, soldering, taping, testing, and other core coil finishing processes, ensuring comprehensive coverage of your coil manufacturing needs. Located on Wisconsin’s beautiful Door County Peninsula, we are committed to providing innovative, cost-effective solutions that exceed customer expectations.

Whether you need a transformer winding machine or any other specialized coil winding solution, we are ready to serve your needs.

Comments are closed