Coil winding machines play a crucial role in manufacturing various types of coils used in a wide range of industries. These machines are designed to wind wires or other materials onto a form to create coils of different shapes and sizes. The type of winding method employed is one key factor determining the type of coils that can be wound using coil winding machines.

Understanding Coil Winding Machines

Before diving into the types of coils that can be wound using coil winding machines, it is important to understand how these machines work. Coil winding machines consist of a spindle that holds the coil form, a wire dispenser that feeds the wire onto the coil form, and a tensioner that controls the tension of the wire as it is wound onto the form. The machine is controlled by a computer that dictates the speed and direction of the winding process, as well as other parameters such as the number of turns and the pitch of the winding.

Types of Coils

Many different types of coils can be wound using coil winding machines, each with its own unique characteristics and applications. Some of the most common types of coils include:

- Toroidal Coils: Toroidal coils are donut-shaped coils that are wound onto a circular form. These coils are commonly used in transformers, inductors, and other electronic devices requiring a compact, efficient coil.

- Solenoid Coils: Solenoid coils are cylindrical coils that are wound onto a straight form. These coils are commonly used in electromagnetic devices such as solenoid valves, relays, and actuators.

- Air-Core Coils: Air-core coils are coils wound onto a form that does not contain a magnetic core. They are used in applications where a high degree of precision and low loss is required, such as radio frequency filters and communication systems.

- Iron-Core Coils: Iron-core coils are coils wound onto a form containing a magnetic core, usually made of iron or a similar material. These coils are used in applications where high magnetic flux densities are required, such as in power transformers and inductors.

- Bobbin Wound Coils: Bobbin wound coils are coils wound onto a bobbin, which is a cylindrical or rectangular spool. These coils are used in a wide range of applications, including motors, sensors, and inductors.

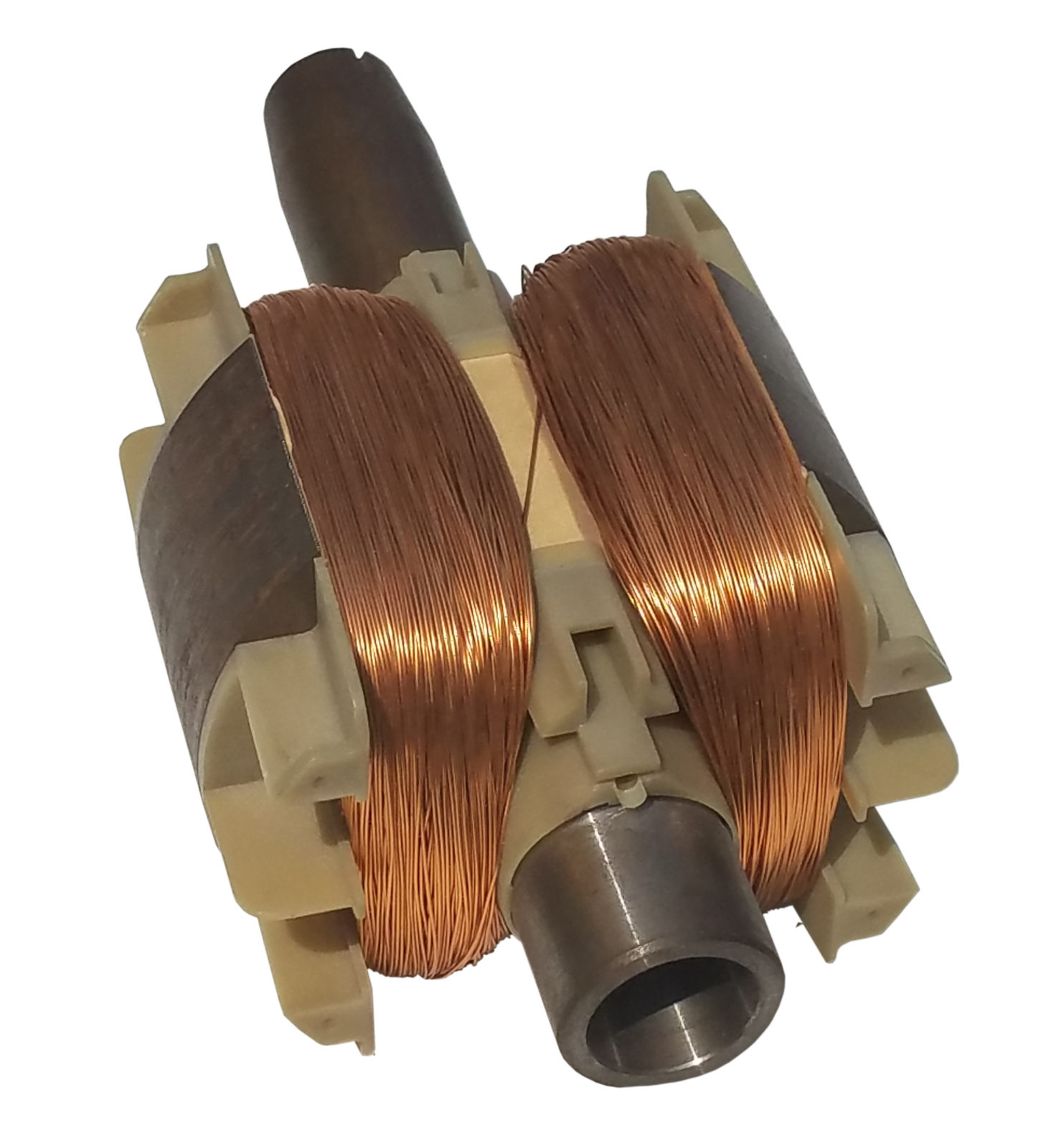

Electrical Core Winder

One key type of coil that can be wound using coil winding machines is the electrical core winder. Electrical core winders wind coils onto cores made of magnetic material, such as iron or ferrite. These coils are commonly used in a wide range of electronic devices, including transformers, inductors, and motors.

Electrical core winders are designed to wind coils onto cores with a high degree of precision and accuracy. The tension of the wire as it is wound onto the core must be carefully controlled to ensure that the coil is wound evenly and without any gaps or overlaps. Additionally, the number of turns and the pitch of the winding must be carefully controlled to meet the specific application’s requirements.

Itasca Automation Systems specializes in designing and manufacturing precision automated machines for the coil winding industry, including electrical core winders. Our engineers use modern 3D CAD tools and a lean modular machine design approach to create customized solutions that meet our customers’ specific needs. Whether you need a multi-spindle winder for high-volume production or a specialized winding machine for a unique application, our team can design a solution that meets your requirements.

Contact Us Today

If you need a high-quality electrical core winder or other coil winding machine, we can help. Contact us today to discuss your specific requirements and learn more about how our team can design a customized solution to meet your needs. Learn more about our products and services and see examples of our work in the coil winding industry. Let us help you take your coil winding operations to the next level with our innovative and reliable automation solutions.

Comments are closed